A Guide to Plumbing Fittings

Choosing the right plumbing fittings is crucial for any plumbing project. Whether you're tackling a simple DIY repair or undertaking a major installation, you’ll want to guarantee secure connections and leak-free plumbing systems by using the right type of fitting.

In this guide, we will explore and compare five common types of plumbing fittings: solder fittings (end feed), solder ring fittings, compression fittings, plastic push fit fittings, and MDPE fittings. Understanding the characteristics and benefits of each type will help you make an informed decision for your plumbing projects.

Join us as we delve into the world of plumbing fittings, comparing their installation methods, durability, versatility, and compatibility with different pipe materials, to help ensure that your next plumbing endeavor is a resounding success.

Solder Fittings (End Feed)

Solder fittings, also known as end feed fittings, are widely used in plumbing applications and are a traditional choice for plumbing installations. These fittings consist of a copper body with no internal stop. They require the use of soldering techniques to create a strong and permanent connection.

Here are some key features of solder (end feed) fittings:

Reliable & durable

When installed correctly, solder fittings provide a secure connection, offering excellent resistance to leaks over time. Their durability ensures long-lasting performance.

Versatile

End feed fittings are available in various sizes and configurations, making them suitable for a wide range of plumbing installations. They can be used in both residential and commercial projects.

Compatibility

Solder fittings are primarily designed for use with copper pipes. They create a tight bond with copper, ensuring a strong connection that can withstand high water pressure and temperature fluctuations.

Permanent connection

Once soldered, the joint created by end feed fittings becomes permanent and difficult to disassemble. This makes them suitable for installations where long-term reliability is a priority.

Industry-standard

Solder fittings have been widely used in the plumbing industry for many years and are considered a reliable and trusted method for creating secure connections.

Professional skills required

It's important to note that soldering skills are required to ensure a watertight joint. Proper soldering techniques involve the application of flux before heating the fitting and applying solder to create a solid connection. This may require some level of soldering experience or the assistance of a professional plumber for accurate installation.

Solder Ring Fittings

Solder ring fittings, also known as Yorkshire fittings or pre-soldered fittings, are similar to solder fittings but come with a pre-applied ring of solder on the inside.

These fittings have several characteristics:

Compatibility

Similar to solder fittings, solder ring fittings are designed for use with copper pipes. They create a secure connection with copper, ensuring excellent durability and resistance to high water pressure and temperature changes.

Convenient & time-saving

The pre-soldered ring eliminates the need for separate soldering, making installation quicker, easier, and more efficient compared to traditional solder fittings.

Reliable joints

Solder ring fittings are trusted in the plumbing industry for their reliability. The pre-soldered ring inside solder ring fittings provides a consistent and reliable seal and robust joints. This ensures a leak-free connection, offering peace of mind, promoting long-term performance, and minimising the risk of leaks and future plumbing issues.

Versatile applications

Solder ring fittings are suitable for a variety of plumbing applications, including both residential and commercial projects. They can be used with copper pipes in different sizes and configurations, providing flexibility in various installations.

Suitable for DIY projects

Solder ring fittings are ideal for DIY enthusiasts or individuals who may not have advanced soldering skills. The pre-soldered ring simplifies the installation process, making it accessible for those with less experience. They are widely used in domestic plumbing projects due to their ease of installation.

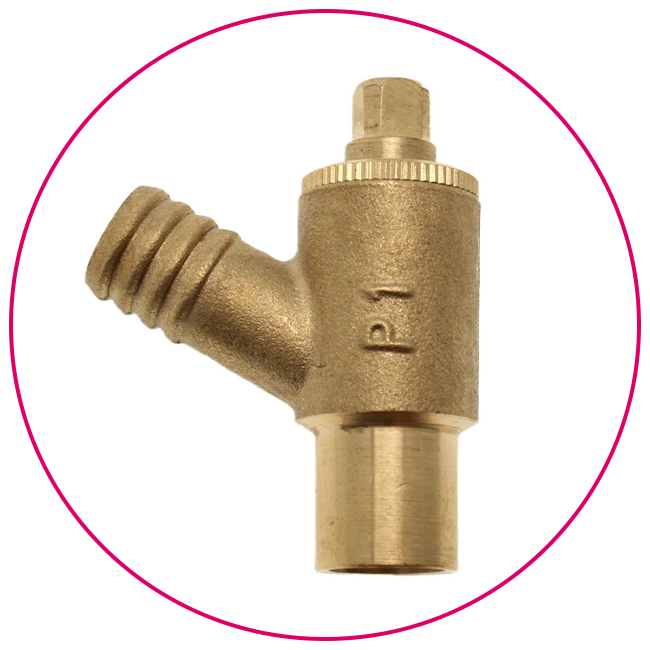

Compression Fittings

Compression fittings are another popular choice for connecting pipes without the need for soldering or specialised tools. These fittings consist of three components: a compression nut, a compression ring (also known as an olive), and a compression body.

Here are some features of compression fittings:

Easy installation

Compression fittings are known for their simple installation process. They can be easily installed by tightening the compression nut, which compresses the olive (compression ring) against the pipe, creating a watertight seal. No soldering or additional sealing materials are required.

Reusability

One of the significant advantages of compression fittings is their reusability. They can be disassembled and reassembled multiple times without losing their effectiveness. This feature is beneficial for situations where adjustments, repairs, or modifications are required. However, we always recommend replacing the olive to ensure a watertight connection.

Versatility

Compression fittings are highly versatile and can be used with various pipe materials, including copper, plastic, and brass. This flexibility makes them suitable for a wide range of plumbing applications.

Secure & leak-free connections

Compression fittings provide secure and leak-free connections when installed correctly. The compression nut creates a strong seal by compressing the olive against the pipe, ensuring a reliable joint that can withstand water pressure and temperature changes.

Compatibility with different pipe sizes

Compression fittings are available in various sizes, allowing for compatibility with pipes of different diameters. This adaptability makes them suitable for both small and large-scale plumbing projects.

Wide range of applications

Compression fittings find applications in both residential and commercial plumbing systems. They are commonly used for connecting fixtures, valves, and appliances, as well as in areas where adjustments or frequent disconnections are necessary.

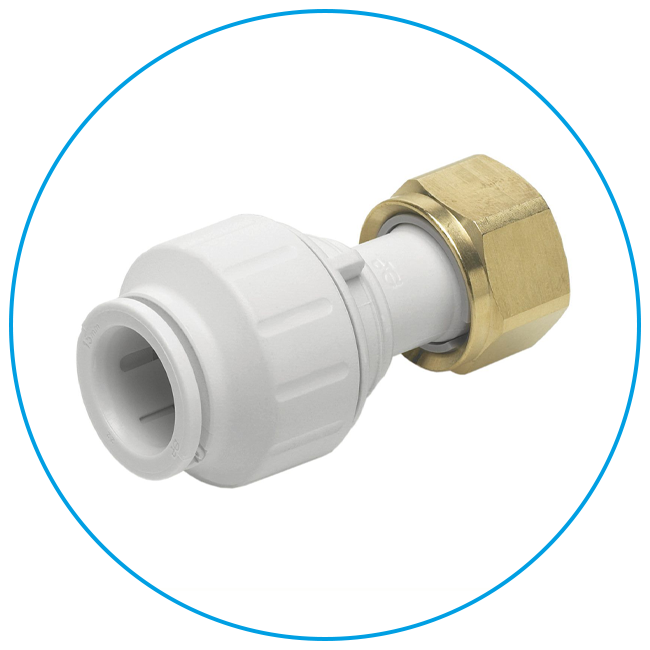

Plastic Push Fit Fittings

Plastic push fit fittings have gained popularity in recent years among professionals, homeowners and DIY enthusiasts due to their ease of installation and versatility. These fittings are designed to connect pipes without the need for any tools or sealing materials.

Here are the key features of plastic push fit fittings:

Simple installation

Plastic push fit fittings offer a user-friendly installation process. They can be connected by simply pushing the pipe into the fitting, which securely grips it with internal seals. No tools, soldering, or additional sealing materials are required.

No soldering or specialist tools required

These fittings are ideal for DIY projects as they eliminate the need for soldering or specialist tools.

Compatibility with multiple pipe materials

Plastic push fit fittings are designed to be compatible with various pipe materials, including copper, PEX, and PVC. This versatility allows for flexibility in plumbing applications, accommodating different systems and project requirements.

Leak-proof connections

Plastic push fit fittings utilize internal seals to create a reliable and leak-proof connection. The seals ensure a tight grip on the pipe, preventing water leakage and promoting a secure joint.

Time-saving

The quick and hassle-free installation of plastic push fit fittings makes them ideal for projects that require efficiency and speed. They are particularly convenient for quick repairs, temporary installations, or DIY projects where ease of use is essential.

Disassembly & reusability

Plastic push fit fittings can be easily disassembled by using a release tool or by hand, depending on the manufacturer, allowing for adjustments, modifications, or repairs. This feature adds convenience and flexibility, as fittings can be reused when necessary.

Wide range of applications

Plastic push fit fittings find applications in both residential and commercial plumbing systems. They are suitable for connecting pipes, fixtures, valves, and appliances, providing versatility in various plumbing projects.

Not cost-effective

Plastic push fit fittings are generally more expensive compared to other types of fittings. This makes them not very budget-friendly as an option for plumbing installations and repairs.

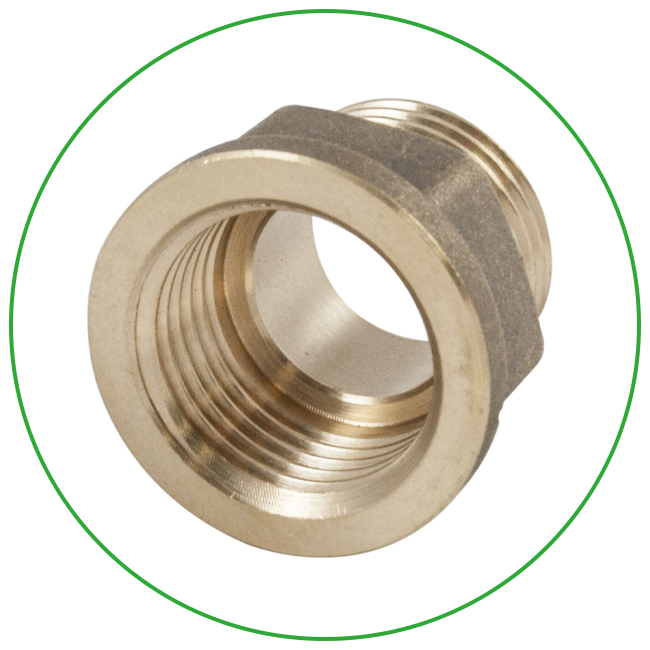

MDPE Fittings

MDPE fittings, or Medium Density Polyethylene fittings, are specifically designed for use with MDPE pipes, which are commonly used for underground water supply systems.

Here are some of the main characteristics of MDPE fittings:

Material strength

MDPE fittings are made from medium-density polyethylene, a durable and robust material that provides excellent strength and resistance to pressure. This makes them suitable for use in underground water supply systems where the pipes may be subject to external forces.

Corrosion & chemical resistant

MDPE fittings offer high resistance to corrosion and various chemicals, making them ideal for applications where the water supply may contain additives or chemicals.

Flexibility

MDPE fittings and pipes exhibit flexibility, allowing them to withstand ground movement and temperature fluctuations without compromising their integrity. This flexibility is particularly beneficial in underground installations.

Leak-free connections

MDPE fittings feature a push-fit or compression mechanism that ensures leak-free connections. The fittings provide a tight and secure seal, minimizing the risk of water leakage and promoting the overall efficiency of the system.

Suitable for underground applications

MDPE fittings are specifically designed for use in underground water supply systems, including domestic, commercial, and agricultural applications. They are commonly used for connecting pipes, fittings, and valves in buried installations.

Easy installation

MDPE fittings typically employ a push-fit or compression mechanism, making installation relatively quick and straightforward. This ease of installation simplifies the process, saving time and effort during plumbing projects.

Longevity & low-maintenance

MDPE fittings are known for their durability and long lifespan. They require minimal maintenance once installed properly, providing a reliable and long-lasting solution for underground water supply systems.

Find the Right Fittings for Your Plumbing Needs

Choosing the right plumbing fitting is essential for achieving reliable and leak-free connections in your plumbing projects. Consider the specific requirements of your project, your skill level, and the desired longevity of the connection to select the most suitable plumbing fitting for your requirements.

As a UK-based heating and plumbing retailer, we offer a wide range of plumbing fittings to suit every job. Our knowledgeable staff can assist you in selecting the correct fittings to meet your plumbing needs and provide expert advice for a successful installation.

Remember, investing in the right plumbing fittings is an investment in the efficiency, reliability, and longevity of your plumbing system. Factors such as pipe material, operating pressure, and temperature should be taken into account when selecting the appropriate fitting for your plumbing system. Choose wisely, and enjoy the peace of mind that comes with secure and leak-free connections in your home or commercial space.

Browse our heating & plumbing range for everything you need for your next heating or plumbing project.